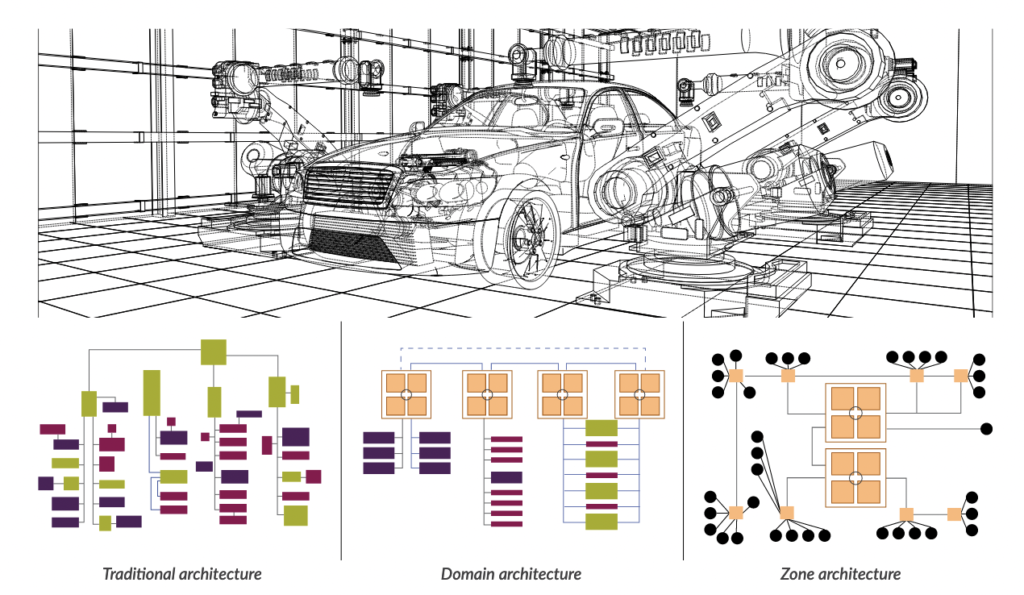

Single Pair Ethernet (SPE) has its origins in the automotive sector. In order to be prepared for the challenges of the future, e.g. with regard to autonomous driving, the data processing of driving information in the car has changed massively. Concepts are changing from an application-oriented structure to a zone-oriented structure. In this process, data obtained from sensors is exchanged between systems. The medium of choice for data exchange is the Internet Protocol (IP). However, the available transmission media for automotive applications were either too large and heavy or not up to the mechanical requirements. Against this background, SPE was developed as a lightweight,

space-saving and inexpensive transmission protocol for Ethernet.

Driven by the need to realize efficiency gains and savings potential, digitization is also being driven forward in every

area of daily life outside the vehicle.

As part of the Internet of Thing (IoT), building automation devices and systems are being networked to make buildings smarter and greener. In the production environment, machines and processes are being intelligently networked as part of the Industrial IoT (IIoT) or Factory 4.0 in order to be able to manufacture in a more flexible, customer-oriented manner with optimized logistics.

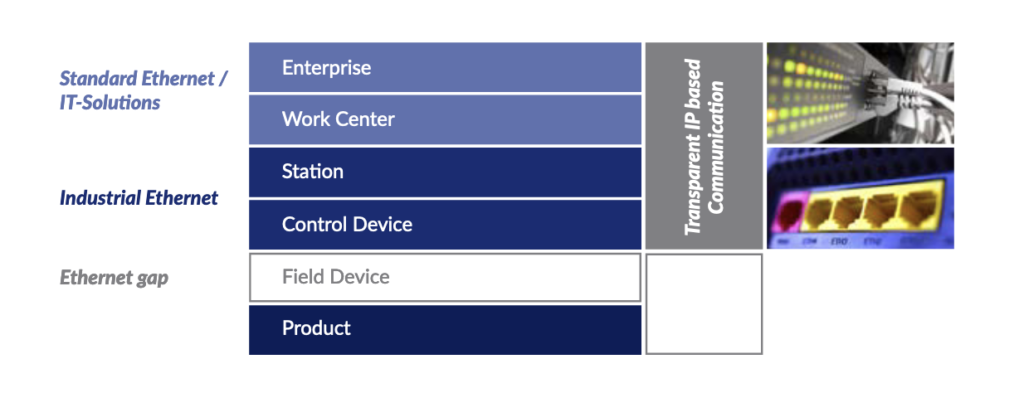

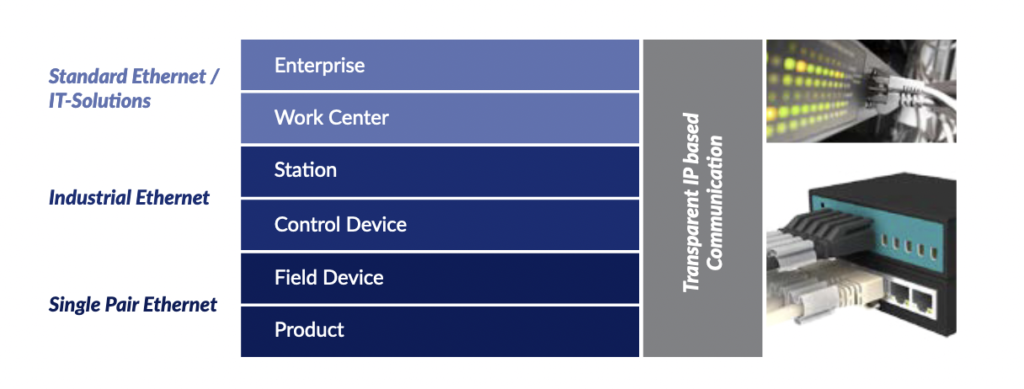

In all these areas, networking with IP has made continuous progress and growing up from the management level the systems that have increasingly been converged. Until now, however, there was a hurdle in connecting individual devices in the sensor/actuator level. Traditionally, proprietary fieldbus systems were necessary here. In order to be able to connect these devices nevertheless, so-called gateways (protocol translators) are necessary. In this context, one sometimes also speaks of the Ethernet gap.

SPE now has the great potential to close this Ethernet gap in industrial, process and building automation. This would enable barrier-free communication from the sensor to the cloud with a single protocol (IP). Consequently, there is a great need to make SPE usable for these areas as well. Consequently, IEEE has developed SPE variants that can cover these new needs.

In fact, many experts expect SPE to be quickly implemented in industrial and process automation. The small dimensions and yet remarkable transmission speed make SPE an ideal candidate for use in protected M8 / M12 housings

or in high-density distribution cabinet solutions.

SPE is also slowly but surely making progress in the field of building automation. SPE can play to its strengths in the development of small sensors and for the miniaturization of networking equipment.

Read the rest of R&M’s White Paper here.